In the world of packaging, stretch wrap, and shrink wrap - are two standard terms that we heard the most, but what sets them apart, and why is Polyolefin Shrink Wrap gaining attention? This comprehensive explanation will explain the distinctions between stretch and shrink wrap, highlighting their unique features, applications, and benefits. We'll also delve into the marvel of Polyolefin Shrink Wrap and its positive impact on the packaging industry.

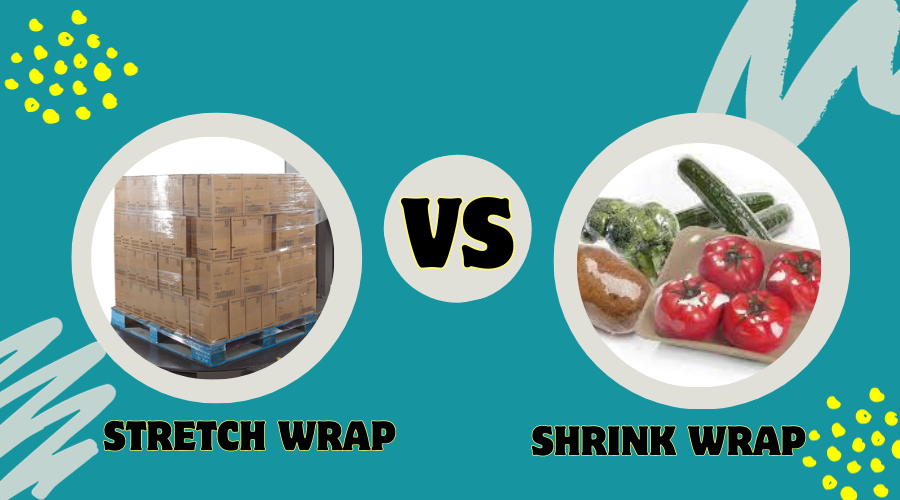

"stretch wrap" and "shrink wrap" are often used interchangeably, but they represent two distinct packaging methods. Let's clear the air on their differences.

Stretch wrap, or stretch film in the packaging field, is a flexible plastic material used to tie and bundle goods together. It is characterized by its stretchability and clingy nature, which allows it to stick to itself and the products it wraps.

Stretch wrap is designed to stretch and recover, which means it can accommodate various sizes and shapes of products, providing a snug fit.

It can be applied manually or by automated machines, offering versatility in the packaging process.

Applications: Commonly used for palletizing products, securing cartons, and bundling items, stretch wrap provides stability and protection during transportation and storage.

Benefits: Stretch wrap provides a cost-effective and eco-friendly solution, reducing the risk of product damage and ensuring load stability.

Here are some typical applications of stretch wrap:

1. Palletizing: Stretch wrap is frequently used to secure and stabilize pallet load. It prevents items from shifting or toppling during transportation and storage.

2. Protection During Transportation: When goods are in transit, stretch wrap helps protect them from dust, dirt, moisture, and other environmental factors, ensuring they reach their destination in good condition.

3. Securing Cartons: Stretch wrap is used to bundle and secure cartons or boxes, making them easier to handle and preventing them from opening during transportation.

4. Unitizing Products: It's used to unitize smaller items into a single package, reducing the risk of damage or loss of individual products and simplifying handling.

5. Furniture Protection: Stretch wrap is commonly used when moving or storing furniture to prevent scratches, scuffs, or damage during handling and transport.

Shrink wrap, on the other hand, is a plastic film that is applied loosely to products and then subjected to heat. When heated, the film shrinks and conforms firmly to the shape of the goods, forming a secure and protective barrier.

Heat Activation: Shrink wrap requires heat for its application, often done using a heat gun or a shrink tunnel.

Tight Conformity: It adheres tightly to the product, providing a tamper-evident and visually appealing package.

Applications: Shrink wrap is widely used in packaging retail products, creating multi-packs, bundling items, and gift basket assemblies.

Benefits: It provides product visibility, tamper resistance, and resistance to external factors, including dust and moisture.

Polyolefin Shrink Wrap, a star player in the world of packaging, thanks to polyolefin shrink film properties, offers distinctive advantages that set it apart from other shrink wrap materials. Let's explore what makes Polyolefin Shrink Wrap a remarkable choice.

Recyclability: Polyolefin Shrink Wrap is easily recyclable, maki ng it an environmentally responsible choice that appeals to conscious consumers and businesses.

ng it an environmentally responsible choice that appeals to conscious consumers and businesses.

Clarity: This material provides exceptional clarity, offering a pristine, glass-like appearance. It showcases products with elegance and captivates customers.

Security: The seal strength of the Polyolefin Shrink Wrap is outstanding. It ensures that products remain securely wrapped, enhancing tamper-evidence and product safety during transportation and storage.

Versatility: Polyolefin Shrink Wrap boasts a wide shrink temperature range, making it suitable for various products, whether you're wrapping food, electronics, or promotional items.

Tear and Puncture Resistance: The film is highly resistant to tears and punctures, offering unparalleled durability. It shields products from potential damage, ensuring they reach their destination in pristine condition.

UV Protection: Some Polyolefin Shrink Wraps provide UV protection, safeguarding products from harmful sunlight that can cause fading and damage.

Polyolefin Shrink Wrap finds its place in a multitude of applications:

Food Packaging: Polyolefin Shrink Wrap is FDA-approved and safe for direct food contact, making it an ideal choice for packaging products such as fruits, vegetables, meat, and more.

Retail Products: Many retail products benefit from Polyolefin Shrink Wrap. From cosmetics to stationery, this versatile material provides an attractive and protective packaging solution.

Industrial and Promotional Items: Industrial products and promotional items are often shrink-wrapped in Polyolefin Shrink Wrap. Its excellent seal strength and durability ensure these items reach customers in pristine condition.

Multi-Packs and Bundles: Polyolefin Shrink Wrap is used to create multi-packs and bundles of products, making it an easy solution for handling and distributing items like beverages and cleaning supplies.

Gift Baskets and Hampers: When it comes to creating elegant gift baskets and hampers, Polyolefin Shrink Wrap is the go-to choice. It adds sophistication and ensures that the contents stay secure and presentable.

Q: Is Polyolefin Shrink Wrap recyclable?

A: Yes, it is! Polyolefin Shrink Wrap is easily recyclable, making it an environmentally responsible choice.

Q: How is Polyolefin Shrink Wrap applied to products?

A: It is typically applied using a heat shrink machine. The film is wrapped around the product, and heat is applied, causing it to shrink and conform to the shape of the item.

Q: Does Polyolefin Shrink Wrap offer tamper resistance?

A: Absolutely. It sticks to the product tightly, creating tamper-evident packaging that safeguards the safety and integrity of your items.

Q: Can Polyolefin Shrink Wrap be used for food packaging?

A: Yes, it can. Polyolefin Shrink Wrap is FDA-approved for direct food contact, making it a safe and attractive choice for food packaging.

In the world of packaging, the difference between stretch wrap and shrink wrap is clear, and Polyolefin Shrink Wrap emerges as a game-changer. Its eco-friendly elegance, unparalleled seal strength, and durability make it a top choice for businesses across various industries. Whether packaging food products, retail items, or creating gift baskets, this versatile material transforms your packaging into an appealing, protective, and cost-effective solution, so the next time you encounter a shrink-wrapped product, you'll not only appreciate its visual appeal but also the tactile satisfaction and the protection it offers, all thanks to the magic of Polyolefin Shrink Wrap.